高耐疲勞性傳動軸件之中空冷間鍛造製程研究

摘要:機車零件之輕量化與精密化為近年來機車零件之製造上發展方向。除可減少能源消耗亦可降低生產成本。在此訴求下,機車傳動軸製造上以中空冷間鍛造製程為創新之方向。本研究首先使用DEFORM模擬軟體進行鍛造製程與模具設計分析,探討中孔擠製衝頭之L/D值設計及整體模具設計。根據模擬結果設計模具零件,並進行鍛造實驗,確認其可行性。結果顯示,本研究共設計6個鍛壓工序,為前擠與四道後向擠壓,最後鍛粗將凸緣成形。依此設計所開發的模具,經小批量鍛打測試,鍛件尺寸符合圖面公差要求且穩定,模具運作亦為順暢,驗證模具設計為可行。此外,所開發的中空冷間鍛造件,經疲勞測試其壽命可達規範要求兩倍以上,顯示品質也獲得提升。

Abstract:Lightweight and precision of locomotive parts has been the development direction of manufacture of locomotive parts in recent years. The lightweight can reduce energy consumption and meet current environmental claims, while the higher precision can improve quality. Due to the demand of lightweight and precision, the manufacture of locomotive drive shafts with precision cold hollow forging forging process is found to be the new trend. In this study, the feasibility of the process and die design was analyzed by using DEFORM simulation software. The design of the extruded hole punch was discussed as well as the overall die design. According to the simulation results, the die parts are designed and the forging experiment is carried out. The results show that The process and die design are feasible after the small amount of trials, which is designed as one stage forward extrusion, four stages back extrusion to gradually make the deep hole and then one stage upsetting to make the flange. The fatigue testing shows the service life of the developed cold hollow forging product is two times as the required service life of the specification. Thus, the quality of the part is improved as well.

關鍵詞:中空零件、傳動軸、長徑比

Keywords:Hollow part, Transmission shaft, L/D ratio

前言

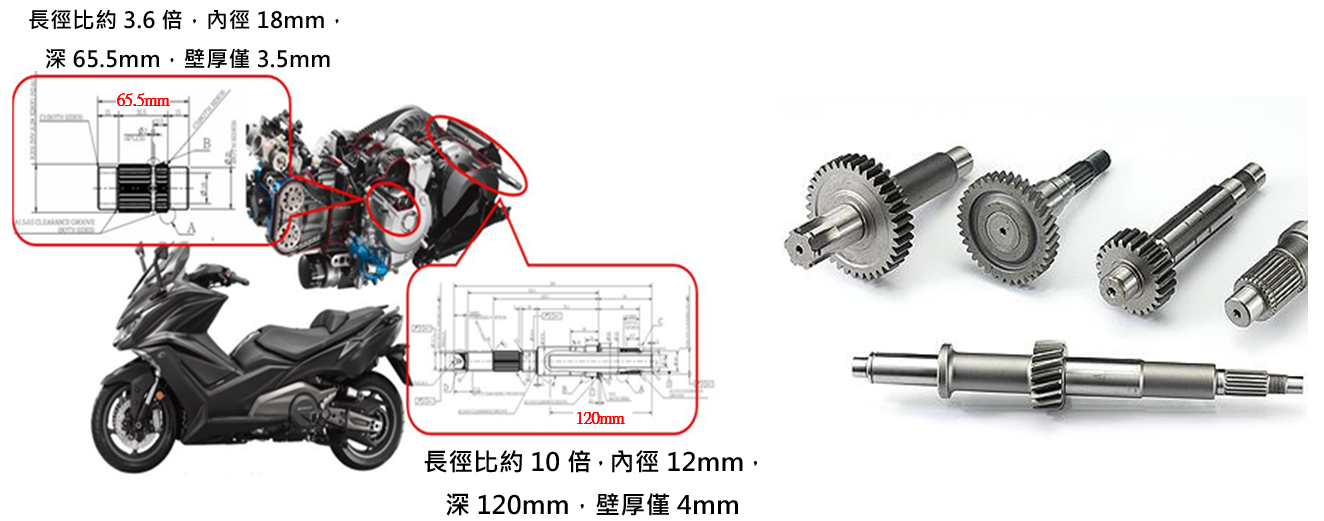

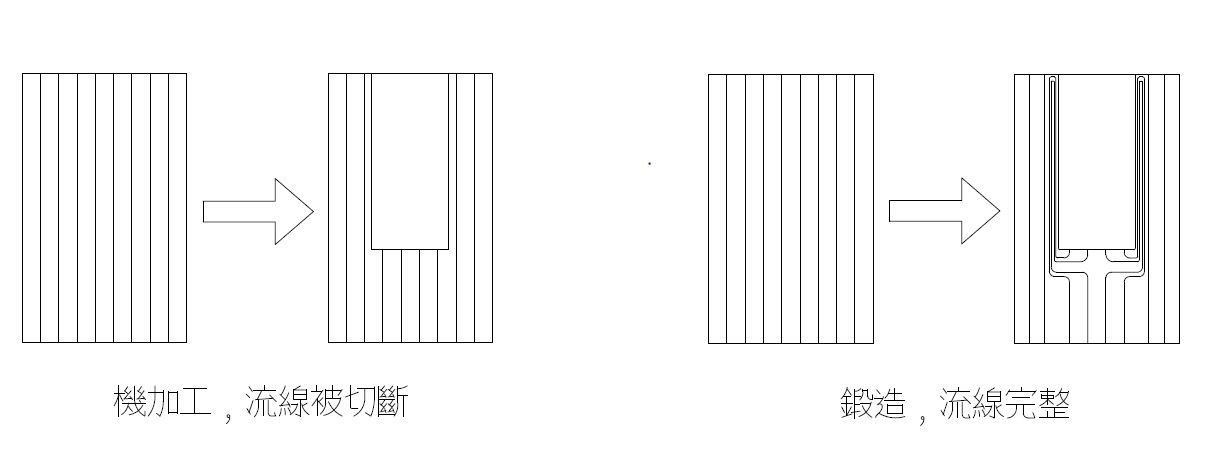

鍛造產品所牽涉的產業範圍極為廣泛,包含:運輸工具、航太、化工、民生、手工具、醫療等各產業之零組件,其產值較大者為汽、機車零組件,約佔60%,且其中鋼鐵鍛造產品產值就佔了180~200億元之間,代表性產品為汽、機車引擎及傳動零件如圖1。在全球面臨原料價格飆漲與節能減碳的趨勢下,汽車零組件的輕量化與省料化,成為機車業者之產品製程技術之發展方向,傳動軸件之製造中空化為可發展項目之一。然國內傳動軸製造之現況,尚停留在傳統製程,以熱間鍛造為主,成形後去毛邊,不僅浪費材料,也耗費能源如圖2。此外,鍛件粗製須大量之機加工。即使是以冷鍛前後向擠出之精密產品,此兩種製程之產品皆為實心,須再進行中孔機械加工,增加機械加工量,同時也將材料內部之鍛造流線切斷,導致耐疲勞性質變差如圖3。由於輕量化中空鍛造技術開發不易,其主要之技術困難點在於後向擠出衝頭之設計,因為每次鍛造時,衝頭之L/D值大於2.5就容易產生挫曲(buckling),導致衝頭斷裂。因此對於中孔較深的鍛胚,需經鍛胚設計,製程模擬分析、模具設計、模具測試過程,才能建立該項技術。因為該項技術具有降低生產成本,提高品質與提升對外競爭力之效益,所以值得去投入開發。

圖1 重型機車傳動軸機構

圖2 傳統機車傳動軸有毛邊之鍛造方式

(a) (b)

圖3 (a)機加工(b)鍛造之流線之比較

…本文未結束

更完整的內容 歡迎訂購 2020年12月號 453期

機械工業雜誌‧每期240元‧一年12期2400元

我要訂購