免模具摺邊工具與機器人核心軟體

技術簡介

傳統汽車鈑金摺邊製程仍需承靠大型客製化模具,而現今機器人摺邊應用多仰賴經驗俱足的師傅費時教導成千點群以生成機器人路徑、鈑金品質亦需長時間試誤找出成型參數。免模具摺邊工具與機器人核心軟體可降低機器人摺邊應用技術門檻並有效降低成本,同時實現少量多樣彈性生產,以滿足現今市場多變之需求。

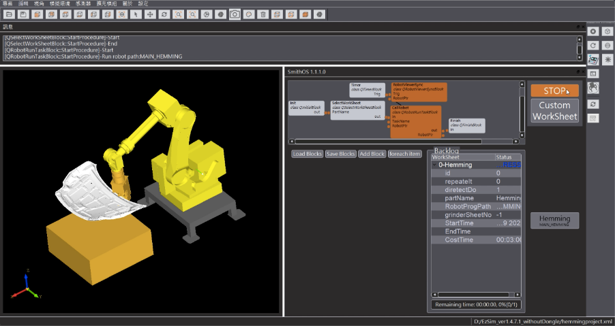

Traditional automotive sheet metal hemming process needs to rely on large custom molds, and today's robotic folding applications rely on experienced masters to teach thousands of points to generate robot paths, as sheet metal quality also requires a long trial and error to find out the molding parameters. The mold-free bending tools and robot core system, SmithOS, has been developed to lower the technical threshold of robot bending applications and effectively reduce costs, while achieving flexible production to meet the changing needs of today's market.

特色與創新

- 免模具摺邊工具,調控正向力300-3000N, 摺邊角0° -60°,尺寸:226 x 246 x 456.5 m3

- 機器人核心系統SmithOS,On-line工單介面與製程參數調控(機器人速度、摺邊力量、摺邊角); 可整合視覺、雷射、力量各感測器

- Mold-free roller hemming tool features the force control range 300-3000N, adjustable hemming angle from 0°-60° and size of 226 x 246 x 456.5 m3

- Robot core system, SmithOS, features user-friendly interface of online modifying the process parameters (velocity, hemming force and hemming angle), support vision, laser and force sensor.

應用與效益

- 汽車鈑金產業,省去模具製造成本與時間

- Applications : Automotive industry, saving cost and time in roller hemming process.

聯絡

更多資訊