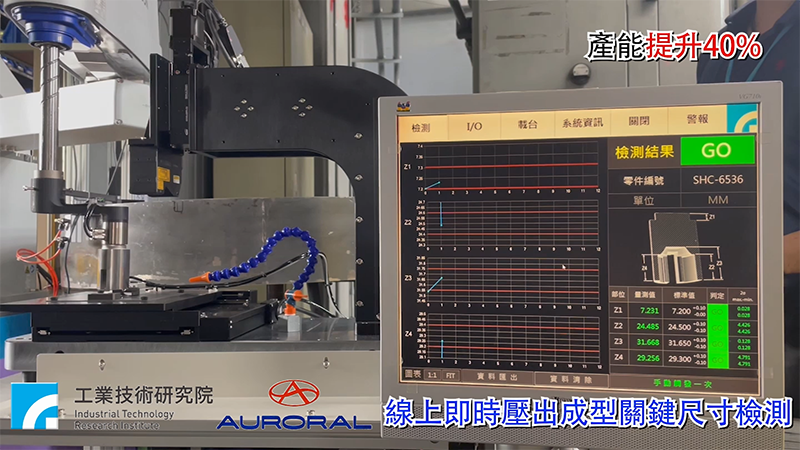

粉末冶金線上成型 關鍵尺寸檢測系統

簡介 Introductions

針對粉末冶金成型壓出之生胚易脆、線上檢測不易、生產速度快,無法使用接觸式量測作為線上即時全檢之品管手段。開發

粉末冶金數位檢測系統,搭配機器手臂達成即時非接觸量測之目的。

Due to the brittleness of the green strength extruded by powder metallurgy molding, the di�culty of online inspection, and the high production rate, it is impossible to use contact measurement as a quality control method for online real-time full inspection. Develop a powder metallurgy digital inspection system, which can be matched with a robot arm to achieve the purpose of real-time non-contact measurement.

特色與創新 Characters and Innovations

- 壓出品質檢測模組:上下對照高精度雷射尺寸量測、精密雙軸微動平台、Z軸升降平台,可針對斷差檢測、內孔、外徑量測。

- 高精度3D關鍵尺寸量測:重覆檢測誤差+/- 0.01 mm、近端檢測寬度≤ 23mm、遠端檢測寬度 ≤ 35mm、檢測深度 ≤ 40mm,零件內凹處深寬比例需 ≤2.5,單次檢測速度 ≤0.5秒/次。

- Extrusion quality inspection module: high-precision laser dimension measurement with upper and lower comparison, precise two-axis micro-motion platform, Z-axis lifting platform, which can be used for step detection, inner hole and outer diameter measurement.

- High-precision 3D key dimension measurement: repeated detection error +/- 0.01 mm, near-end detection width � 23 mm, far-end detection width � 35 mm, detection depth 40 mm, the depth-width ratio of the inner concave part of the part must be � 2.5, single detection speed � 0.5 seconds / time.

應用與效益 Applications and Benefits

- 協助國內粉末冶金成型業者(A公司)有效提升產線品質與良率。產能提升40%、品質良率提升50%。

- Assist the domestic powder metallurgy molding industry (Company A) to effectively improve the quality and yield of the production line. Production capacity increased by 40%, and quality yield increased by 50%.

線上檢測情境