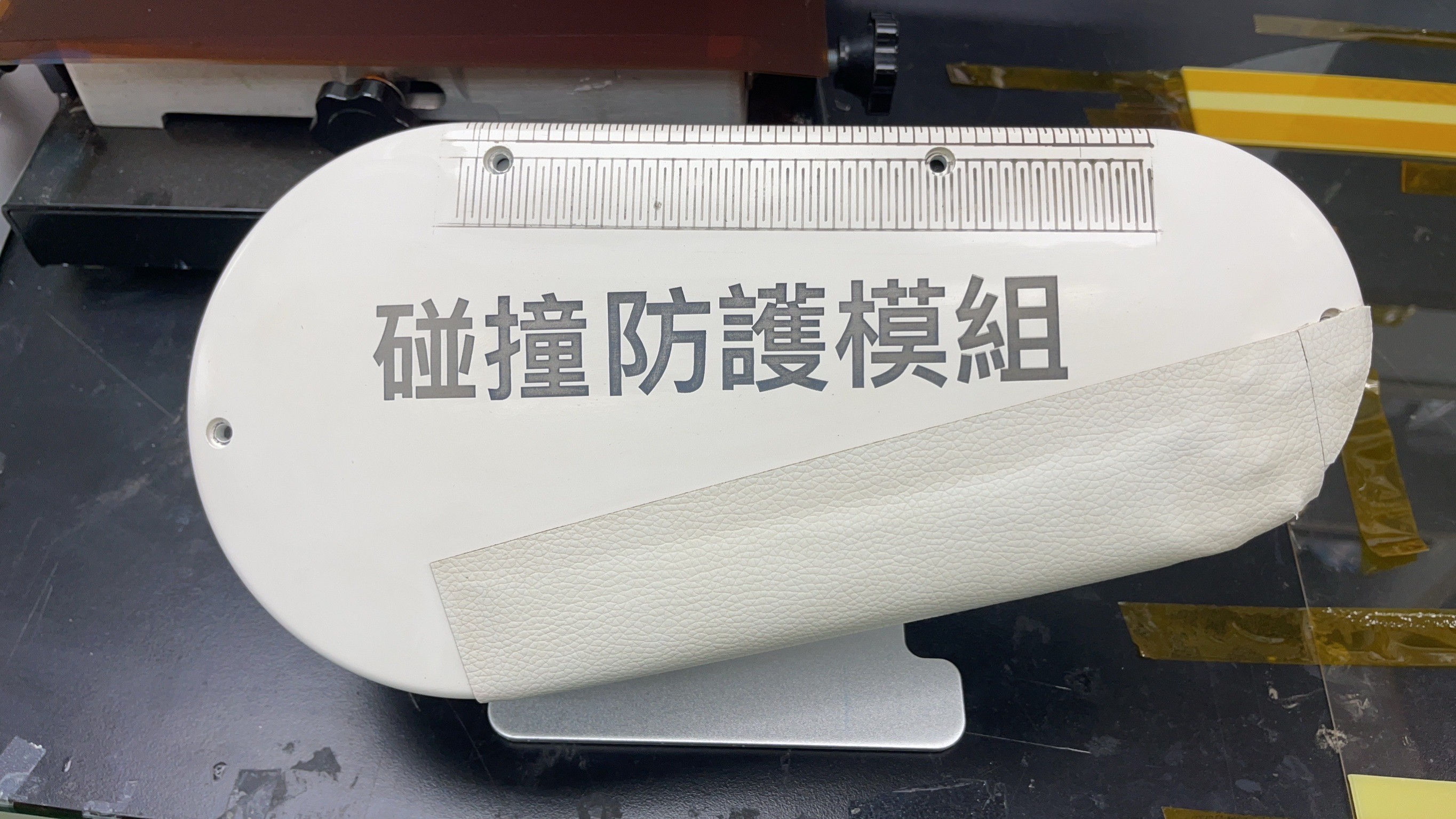

機器人碰撞防護模組

簡介 Introductions

發展3D金屬線路圖案化製造技術,整合氣旋噴印系統與可金屬化之膠體材料,在機器人外殼表面直接噴印圖案化與金屬化感測線路。機器人外殼的感測模組可即時(<5msec)感應到碰撞(5N~100N),發出停機訊號,使機器人作動停止,以確保人機協作的安全防護。

Collision-sensing module is developed using 3D metal circuit patterning manufacturing technology. The module integrates an aerosol jet system and colloid materials to pattern directly the sensing circuit on the surface of the robot shell. The technology senses the collision (5N~100N) in real time (<5msec) and sends out immediately an abort signal to stop the robot motion to ensure the safety protection of human-machine cooperation.

特色與創新 Characters and Innovations

- 模組技術可因應工業機器人的多曲率外殼,利用氣旋噴印系統直接噴印圖形化以及金屬化的感測線路。

- 模組的感測線路包覆率極高(>90%),並且在感知力度(5N~100N)後,可觸發停機訊號,提升人機協作安全程度。

- 模組技術不僅可偵測到機器人大部份的碰撞情況,亦可感應到作業員被機器人捲夾的力道。

模組技術適用於機器人終端使用廠商,其在有限的廠區裡具備大量且多種不同外形的機械手臂,如金屬加工廠、食品加工廠、電子組裝廠等產業。

The collision-sensing module is printed directly on the surface of the robot shell with the aerosol jet system.

The coverage rate of the protective lines on the robot shell exceeds 90% and the sensing force (5N~100N) causes an abort signal to the robot for improving the safety factor of human-machine cooperation.

The module not only detects most kinds of collisions, but also senses the clamping force caused by the robot to operators due to the narrow working space.

The module is suitable for end users of robots, which have many different shapes of robots in a limited factory area, such as metal processing factories, food processing factories, electronics assembling factories etc.

應用與效益 Applications and Benefits

多機協作生產製造單元。

Multi-robot collaborative manufacturing cell.