快拆式驅控整合關節模組

簡介 Introductions

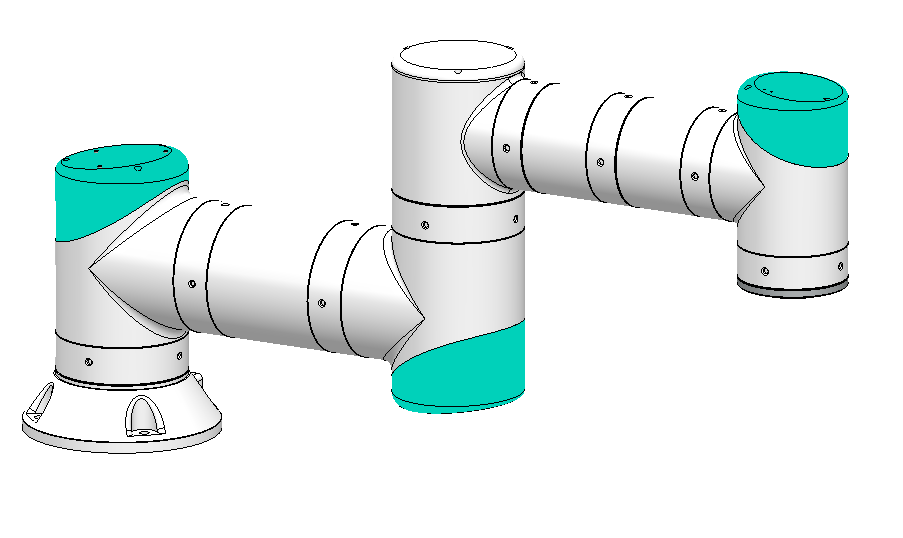

快拆式驅控整合關節模組,似樂高積木一樣簡易堆疊組裝成不同型態之機器人,在所有產業皆有相關應用,諸如零件組裝、

輕工業加工、物料檢測與處理、醫療手術輔助等。傳統機器人為整機出廠且型態固定,若想更換用途或維修必須整機拆換;

而透過本技術導入快拆式機器人關節,可以大幅縮短拆換組裝的時間降低成本。

The Detachable Joint Robot System of ITRI can be easily stacked and assembled into different types robot like blocks. This design concept can be applied to various use case, such as part assembly, light industrial processing, material inspection and processing, and surgical assistance, etc. Traditional robots is a complete machine with a fixed shape. Have to disassemble and assemble whole machine if purpose change or repair requirement. Applying the Detach-able Joint Robot System could substantially reduce disassembly and assembly time and cost.

特色與創新 Characters and Innovations

- 可彈性適應各種產業,從成本或需求考量建構機器手臂應用。

- 模組化設計,可調整自由度與臂長,提高機器手臂稼動率。

- 具備機器人關節快速拆換機制,僅需替換有問題之關節模組,降低維修費用與時間成本。

- 具備可視化程式編輯系統,降低使用者操作難度。

- 具備機器手臂順應教導功能,能讓使用者以拖拉方式將手臂移動至目標點位。

- 機器人高精度提升技術,可提高受控手臂定位精度。

- It can flexibly adapt to various industries and construct robot arm based on cost and demand consideration.

- Modular design. Can adjust degree of freedom and arm length to improve the availability of robot arm.

- Quick joints replacement. Only replace defective joint and reduce maintenance cost and time.

- Visual program editing system to reduce the difficulty of user operation.

- Equipped with robot arm compliance teaching function. Users can move the arm to target points by dragging.

- High precision lifting technology of the robot can improve the positioning accuracy of the robot arm.

應用與效益 Applications and Benefits

- 自動化和生產效率提高:數位化工廠中自動化系統中的致動器(Actuator)。

- 產品應用多樣化:多軸關節機器人在水平式、垂直式等環境應用方面具有高度的彈性。

- 促進創新和技術進步:機器人教育訓練、DIY 市場、技術驗證用途、服務型機器人。