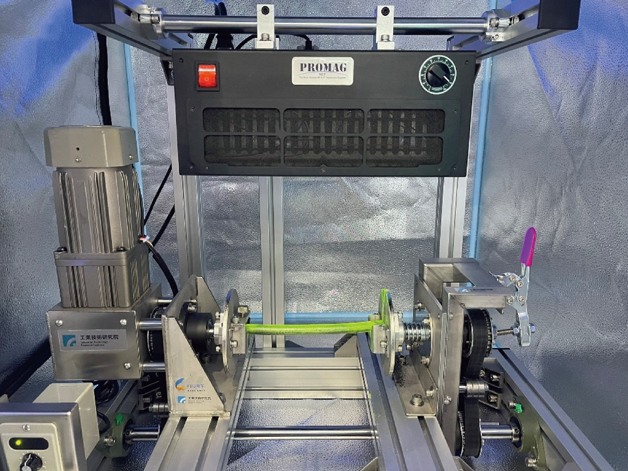

光檢傷模組

本模組結合傳統機器視覺和深度學習之優勢,解決現有針對表面裂痕其螢光顯影後磁檢設備商無法智慧檢測問題,透過此AI智慧檢傷模組進行瑕疵檢測,減少人員負擔,提升國內磁檢設備競爭力。

T module combines the advantages of traditional machine vision and deep learning technology, to address the issue faced by manufactures of magnetic particle inspection (MPI) equipment, who cannot inspect surface cracks after magnetic testing. Through the AI intelligent inspection module of ferromagnetic materials, a re-judgment mechanism for suspicious defect inspection can be carried out. This reduces the burden of operator, increasing the in telligent function of magnetic particle inspection, and enhancing the competition of domestic MPI equipment.

技術特色 Technical features

- 智慧AI技術:透過AI檢測功能的加值,解決傳統自動化檢測設備易誤判問題,原誤判率超過20%,現可降低至8.62%,且不會有漏檢的瑕疵。

AI intelligent inspect: Overcoming the problems of traditional AOI equipment. Through the AI inspection module to achieve automated inspection in magnetic particle inspection equipment.

- 線上模型更新:可透過網路更新優化檢測模型能力,大幅減少現場人員作業負擔。

Suspicious defect re-judgment mechanism: Through the suspicious defect re-judgment mechanism, operator can be reduced.

應用效益

- 降低人力需求:可降低75%之人力需求,將人員素質提升至做更高等級工作。

Reduce labor costs: This module can reduce manpower requirements by 75%, enabling personnel to engage in higher-level work and improving overall quality.

- 全天24小時檢測:加值設備價值至少提升兩倍以下。

Work 24/7: AI-inspecting equipment can detect and produce 24 hours a day, 7 days a weeks, providing at least double the value of equipment. This significantly enhances equipment efficiency and competitiveness.